Renovation debt of water supply and wastewater networks drives Oulu Waterworks to develop effective construction methods and increase investment volumes. The use of no-dig methods so far, have covered a minority of all Oulu Waterworks’ network building projects but were typically greater in scale and monetary value. Implementing no-dig methods reliably and justifiably to be the first choice of operation was needed and the demand led to the creation of a research-oriented thesis also offering a practical point of view. The main goal of the thesis was to justifiably present an increase in renovation investment volumes of water supply and wastewater networks that are outside the scope of joint-projects and traditional open-cut construction methods. Thesis results show that Oulu Waterworks’ investment volumes are behind the preferred volumes. No-dig methods can be the factor to reach the gap when their potential use is acknowledged and are used accordingly. An increase in investment volumes is recommended.

Renovation debt of critical water infrastructure in Finland has been increasing [1]. Leakage, clogging, and collapse repairs hold the network together but is not a sustainable solution to look ahead. Joint project area renovations alone are not enough to tackle the debt. Permits and contracts for design and construction of pipelines have become harder to obtain. At the same time old and unmapped networks are found in places that make traditional digging and renewing processes very challenging. This leads to the need to devise a cost-effective, time saving, permit-friendly, environmentally acceptable, and high-quality method for critical water infrastructure rehabilitation. [2]

The present state of the networks

Oulu Waterworks’ network consists of the central Oulu area, or so called pre-municipal merger Oulu and the merger municipalities. [3] Water supply network and wastewater sewer network both doubled their length during the mergers. [4]

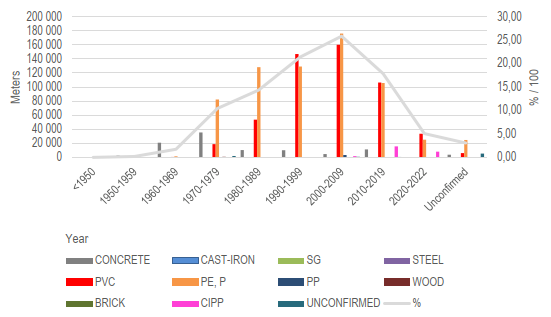

The length of the water supply network is almost 2 000 kilometers. Of all water supply pipes, 90 percent are made from plastics and 43 percent are from the 1980s and 1970s. The length of the wastewater network is almost 1 350 kilometers. Of all wastewater sewer pipes, 89 percent are made from plastics and 32 percent are from the 1980s and 1970s. (Figures 1 and 2.) Considering 50 years the lifecycle for older networks, large quantities are bypassing this mark in the coming years or already have bypassed it. There are also other significant factors to be considered when planning future renovations.

Renovation debt and investment levels

Yearly investment needs in Finnish water sector are set to double themselves between years 2020‒2040 and is projected to increase even after this. By evaluation, as much as 12 percent of wastewater network assets and 6 percent of water supply network assets are labelled to be in extremely poor condition. The needed water supply network renovation investment volume is calculatorily 1.1 percent of total water supply network length per year and 1.9 percent for wastewater network. This means about double its current volume for water supply network and about triple its current volume for wastewater network. The increase should be done quickly, for there are even larger network amounts in need of renovation in the future. This will be a key factor in ensuring the continuity of protected water services in Finland. [1]

Investment levels of Oulu Waterworks

Renovation debt in Oulu area has been increasing since the beginning of the 21st century. During years 2000 to 2010 water supply network has been renovated approximately 0.6 percent of the total length at the time and 0.55 percent for wastewater network. The investment percentages should have been increased to 1.1 percent and 1.9 percent in the following years to keep the debt from increasing. [6]

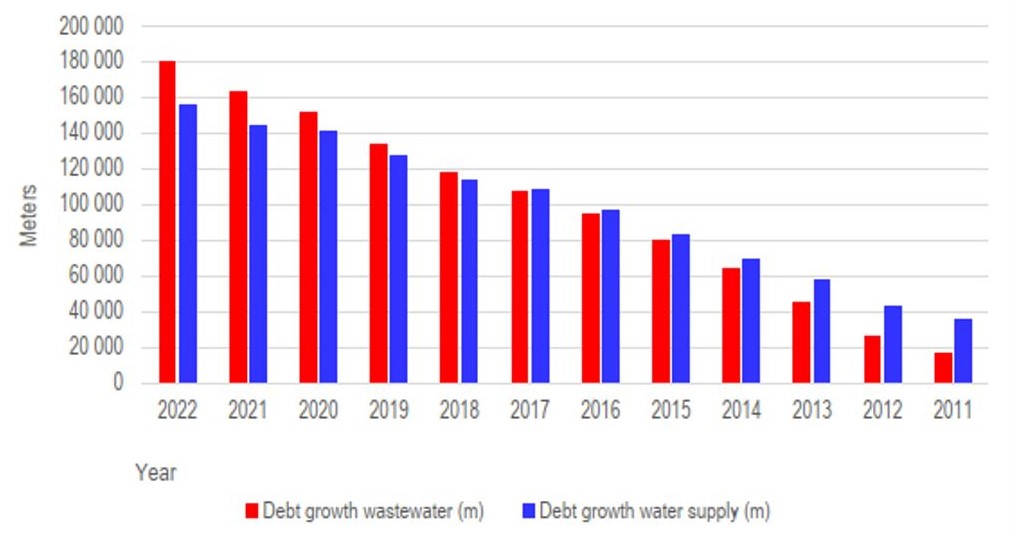

Years 2012‒2022 investment volumes have not significantly increased and have been quite steadily even, despite the network doubling its length in 2013 (figure 3). The gap between preferred levels and the actual levels during the years for water supply was an average of 0.6 percent. The gap for wastewater was an average of 1.22 percent. Results meant that investment levels were 2 to 5 times too low when compared to the preferred levels. (Figure 4.) The debt in 2012 was 35.5 kilometers for water supply and 17 kilometers for wastewater network.

In the end of year 2022 the debt was 156 kilometers for water supply and 180 kilometers for wastewater network (figure 5). The debt percentage for wastewater was 13.4 of the total network length and the debt percentage for water supply network was 7.91 of the total network length (figure 6). The debt percentage in water supply network had multiplied itself by 1.84 and the debt percentage in wastewater network had multiplied itself by 3.47 in 11 years.

No-dig methods

There was a need to grasp more actual field knowledge on initial data, benefits, potential cost-saving, suitability, and risks of Oulu Waterworks’ most used no-dig, trenchless or minimal open-cut pipeline rehabilitation methods. Thus, an interview in form format was sent to known no-dig contractors, no-dig field expert consultants and other waterwork experts.

In the thesis, only the most common used no-dig and minimal open-cut methods in Oulu Waterworks’ water infrastructure construction projects are addressed and focus was purely on certain key factors. There are multiple more different no-dig methods that are not mentioned. The development of different and existing methods is growing and as time advances many can find their way to Oulu Waterworks’ projects as the possibilities present themselves.

As the planning of a project is starting, a first quick evaluation of construction needs is done: what needs to be done and how to achieve that goal. The initiator must be enlightened of traditional and no-dig methods, which means a deep understanding of key factors in selecting a construction method and their needs for initial data but also their limits. [2] Key factors for evaluating a no-dig method must be identified. In the work, these factors chosen for water pipeline renovation are initial data, benefits, potential cost-saving and risk evaluation.

All factors were determined for cured-in-place pipe (CIPP), slip lining, pipe bursting or splitting, horizontal directional drilling (HDD) and for jacking, ramming, drilling and auger boring. Most common traits for the methods are environmental benefits, both natural and built, timesaving and the need for as much initial data as there can be.

Case: Construction project

A project of this scale of nearly four kilometres for this specific mainly 110 to 160 mm polyethylene plastic pipes had not been done in any of Oulu Waterworks’ projects. It was determined in the design phase (image 1) that the network in the project area was so problematic that it could not be done with traditional digging without causing large disruption and uproar in residents. Therefore, it led to determining how it could be done with minimal open-cut and save as much of the built and natural environment as possible.

The design and construction (image 2) project put the statistically two most common water supply pipes to a renovation test. 110- and 160-mm polyethylene plastic pipes from the early 1970s were the dominant existing pipelines during the project. There had been multiple leaks in the network. Approximately half of the water supply lines in the project were located inside the property lines of private properties. The pipeline locations made it extremely difficult to renew with traditional digging.

Pipe diameters could not be decreased. It was then chosen to use pipe splitting (image 3) as the main construction method and slip-lining as the secondary method with a possibility of horizontal directional drilling. Excavation would only be used when necessary. Throughout the project the pipes split quite well. Slip-lining and horizontal directional drilling were also used. In the end, almost 4 kilometers of water supply pipe was renewed. (Image 4.) Overall, the project was seen as a success and valuable field information was gained.

Development of investment levels

The main goal of the thesis was to justifiably present an increase in renovation investment volumes of water supply and wastewater networks that are outside the scope of joint-project and traditional open-cut construction methods.

Results show that renovation debt has been rising from the 2000s and has seen a more rapid increase in years 2012‒2022. Renovation investment levels should be increased two times greater for water supply network and three times greater for wastewater network.

Financing the increases can be potentially problematic and generates risks. Too high a rise of collection fees from consumers can be hazardous for an individual water consumer and potentially exponentially increase costs of high-end water consumers, twisting markets. Currently Oulu Waterworks relinquishes an amount of its own yearly operating surplus to its owner, City of Oulu. In year 2022 the amount was 6.6 million euros. Considering the amount needed to increase investment levels, Oulu Waterworks should direct the amount 100 percent to its own use to keep renovation levels up and consumer prices acceptable. Government funding should be considered.

It can be deduced that most of both networks are made from plastic materials and are of smaller diameters. Considering 50 years is the life expectancy of older existing networks, the larger volume sooner coming to renovation age is from water supply networks. Still, over 1/10 of wastewater network is going to pass over the 50-year mark in the next few years or already is over it. The year of construction is not the only factor deciding the need for renovation and other significant factors should also be considered when planning future renovations.

Insightful and actualised information was gained from the design and construction project and field survey of known no-dig experts. The results show that initial data and the know-how of different methods generate the best outcome. The construction project results show that no-dig methods can be cost-efficient even when the tender price is seen exceeding planned value. They also show that the benefits of no-dig installations to the environment are indisputable. The quality of no-dig installations is no less than the quality done by traditional digging. Landowner contract managing benefits greatly from no-dig as residents are more indulgent to the entire project. Taking these into account, it can be said that no-dig methods can be an enabling factor when planning renovation projects.

It can be concluded that Oulu Waterworks should increase renovation investments levels quickly. No-dig methods can be the enabling factor of projects outside the scope of joint-project and traditional open-cut construction methods. The knowledge, know-how and evaluation of construction methods for different project types is a key-factor to a successful outcome. It remains to be seen how rising investment levels and executing more projects entangle with implementing no-dig methods to the mix.

Mohamed Asheesh

Principal Lecturer

School of Engineering

Oulu University of Applied Sciences

Elias Haapaniemi

Construction Project Manager

Oulu Waterworks

Article is based on the thesis: Haapaniemi, E. 2023. Investment levels and the use of no-dig methods at Oulu Waterworks. Oulu University of Applied Sciences, Water and Environmental Management (YAMK). Thesis. https://urn.fi/URN:NBN:fi:amk-202205118593

References

[1] Kuulas, A., Renko, T. & Kuivamäki, R. 2020. Vesihuollon investointitarpeet vuoteen 2040. Vesilaitosyhdistyksen monistesarja nro 63. Afry Finland Oy. Accessed 7.2.2023. https://www.vvy.fi/ohjeet-ja-julkaisut/hallinto-ja-talous/vesihuollon-investointitarpeet-vuoteen-2040/

[2] Hekkala, A. 2023. Interviews. Senior construction project manager. Oulu Waterworks.

[3] Oulun kaupunki, Konsernihallinto. 2022. Oulun kaupungin tilastollinen vuosikirja 2021. Accessed 13.4.2023. https://www.ouka.fi/documents/50085/832671/Tilastollinen+vuosikirja+2021_/558df9ed-cb44-4073-a610-5399c86b896e

[4] Oulun Vesi. 2023. Vuosikertomus 2013. Accessed 5.5.2023. https://issuu.com/gstgraafinenstudio/docs/oulunvesi_2013

[5] Haapaniemi, E. 2023. Investment levels and the use of no-dig methods at Oulu Waterworks. Oulu University of Applied Sciences, Thesis. Accessed 19.9.2023. https://urn.fi/URN:NBN:fi:amk-202205118593

[6] Pietarila, V. 2012. Oulun vesihuoltoverkoston saneerausvelan määrittäminen. Oulun University of Applied Sciences. Thesis. Accessed 13.4.2023. https://urn.fi/URN:NBN:fi:amk-201204305531

Vastaa

Sinun täytyy kirjautua sisään kommentoidaksesi.